- Sustainable Cementitious Products

- Microsilica

Microsilica – Enhancing Concrete

Strength and Durability

Product Overview

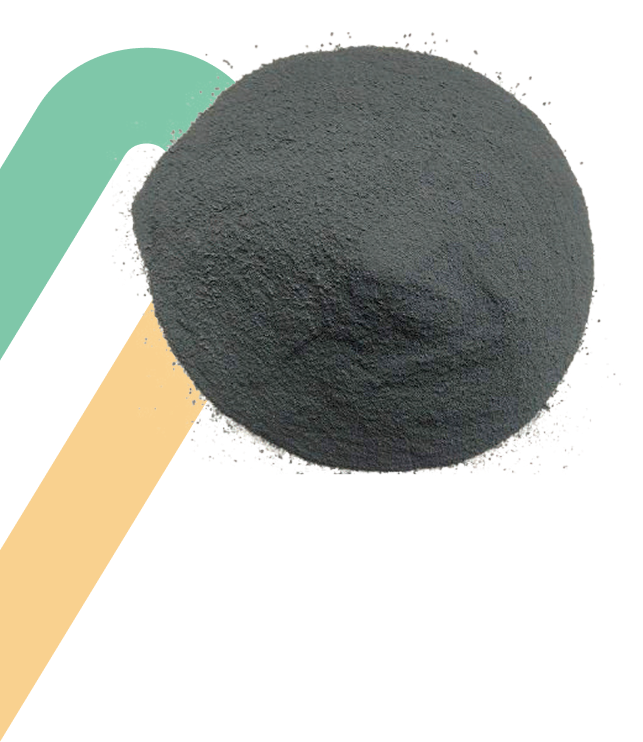

Microsilica

Product Type:

Supplementary Cementitious Material (SCM)

Description:

Microsilica, also known as silica fume, is an ultrafine powder produced as a byproduct of the silicon and ferrosilicon alloy production process.

It consists of very fine spherical particles rich in silicon dioxide (SiO2).

Microsilica is a highly reactive pozzolan and is used to enhance the properties of concrete and other construction materials.

Source:

China, Malaysia, South Africa, France & Spain

Unlocking the Full Potential of Microsilica

Key Features

High Reactivity

Microsilica is highly reactive and provides excellent pozzolanic properties, improving concrete strength, durability, and other properties.

Reduced Heat of Hydration

It helps in controlling the heat generated during the cement hydration process.

Reduced Permeability

It significantly reduces the permeability of concrete, making it highly resistant to chloride ion penetration and sulfate attack.

Enhanced Durability

Microsilica improves resistance to alkali-silica reactivity (ASR) and enhances freeze-thaw resistance.

Increased Strength

Microsilica contributes to increased compressive and flexural strength in concrete.

Environmental Benefits

Using microsilica in concrete reduces the carbon footprint, making it a sustainable choice for construction projects.

Versatile Applications

Microsilica enhances durability and strength, making it ideal for critical infrastructure and challenging environments.

High-Performance Concrete

Microsilica is used in high-strength and high-performance concrete to enhance strength, durability, and impermeability.

Self-Compacting Concrete

It is used in self-compacting concrete mixes to enhance flowability and strength.

Shotcrete

It is utilized in shotcrete applications, such as tunnel linings, to achieve high strength and resistance to harsh environmental conditions.

Pre-cast Concrete

Microsilica is valuable in pre-cast concrete products, including panels, beams, and columns.

Bridge Decks

Microsilica improves the durability of bridge decks, making them more resistant to corrosion and extending their service life.

Grouts and Repair Materials

It enhances the properties of grouts and repair materials for structural repairs.

Technical Specifications

Optimizing concrete performance with superior strength, durability, and sustainable benefits.

| Properties | Unit | ASTM C618 Class F |

|---|---|---|

| Silicon Dioxide (Si02) | % | 85 Min |

| Moisture Content (H2O) | % | 3.0 Max |

| Loss on Ignition (L0I) | % | 6.0 Max |

| CI | % | 0.1 Max. |

| Surface Area | % | >15m2/g |

| Pozzolanic Activity Index (7 days) | % | ≥ 105 |

| Fineness at 45-micron sieve | % | 10 Max |

Masheed’s commitment to sustainable construction

Ensuring Excellence: Quality,

Storage, and Sustainability

Quality Standards:

Microsilica products conform to ASTM C1240

and other international standards for

supplementary cementitious materials.

Storage and Handling:

Store microsilica in a dry environment to

prevent moisture absorption. Handle with

care to minimize dust generation

Environmental Benefits:

Using microsilica in construction materials significantly reduces greenhouse gas emissions and conserves natural resources. It is an environmentally responsible choice for sustainable construction practices.