Sustainable Cementitious Materials

to Build Greener Future

Masheed is leading the shift towards sustainable cementitious materials by providing high-quality, materials that enhance performance while reducing environmental impact.

Our Sustainable Cementitious Materials Benefits

Reduced Carbon Footprint

Cement replacement materials, such as microsilica, flyash or GGBFS help in significantly lowering CO2 emissions in the final product. By opting for these alternatives, builders can make a substantial contribution to reducing the construction industry's environmental impact.

Long-Term Sustainability

By using cement replacement materials, builders are investing in the longevity and sustainability of their structures. These materials are known for their durability and resilience, reducing the need for repairs and replacements, which further minimizes environmental disruption.

Sustainable Sourcing

Our cement replacement products are designed to make the most efficient use of resources. By reducing the need for traditional cement, these materials help conserve valuable natural resources like limestone and clay.

Resource Conservation

We take pride in sourcing our materials responsibly, ensuring they come from environmentally friendly and ethical sources. This commitment to sustainability goes hand in hand with the principles of environmentally conscious builders.

Energy Efficiency

Cement replacement materials are byproducts from industrial processes. They need less energy than traditional Portland cement, which is made by high-temperature calcination of limestone.

Regulatory Compliance

Our products adhere to industry standards and certifications, demonstrating our commitment to environmentally ASTM C618 and BS EN 450 standard friendly construction practices.

Discover Our Products

Fly Ash

Boost performance, reduce cracking,

and reduce CO₂ footprint

Fly ash is a sustainable by-product of coal combustion that enhances concrete durability, reduces permeability, and minimizes environmental impact.

Used in concrete production, road construction, and brick manufacturing, it reduces CO₂ footprint and conserves natural resources.

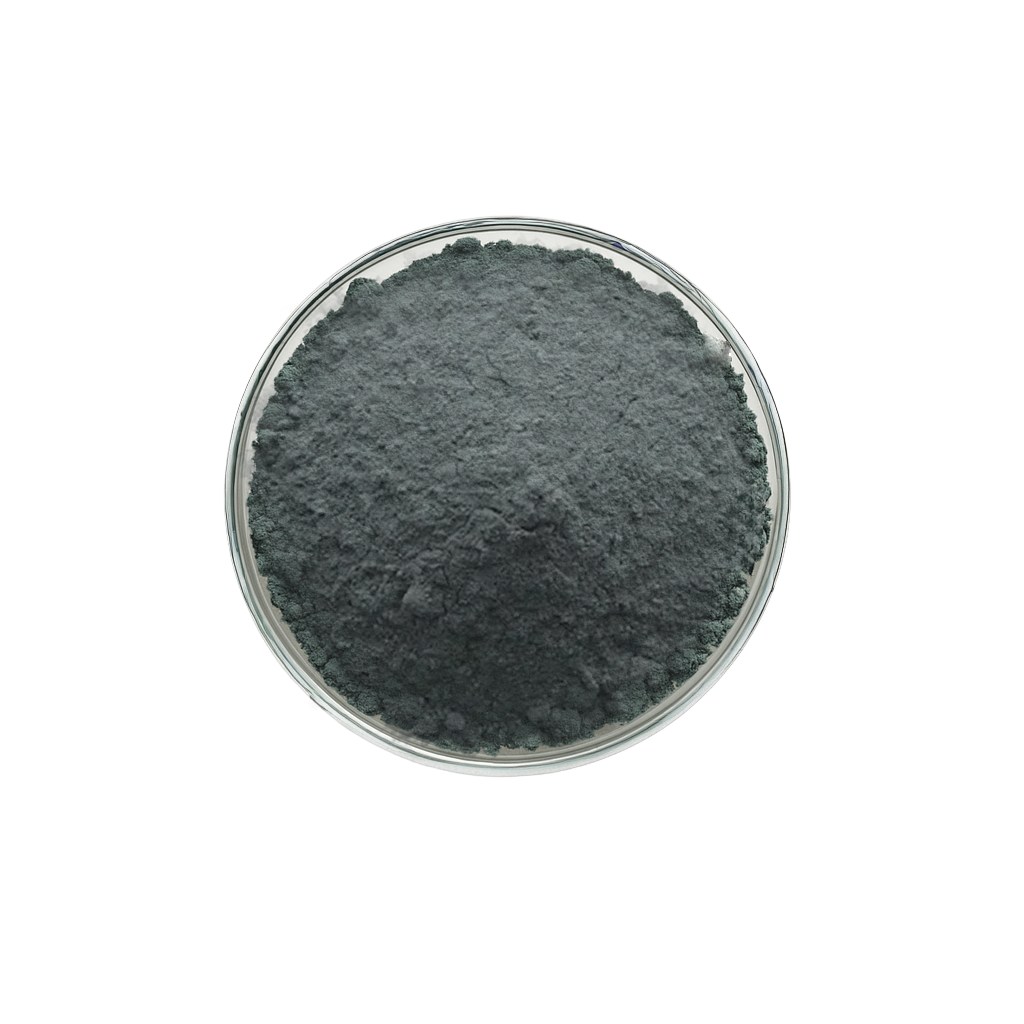

Microsilica

A high-performance additive that boosts strength and durability

Microsilica, also known as silica fume, is an ultra-fine byproduct of silicon metal and ferrosilicon alloy production.

With its high reactivity and fine particle size, it significantly improves concrete’s strength, chemical resistance, and overall durability. Additionally, it contributes to sustainability by reducing water usage, lowering carbon footprints, and conserving energy.

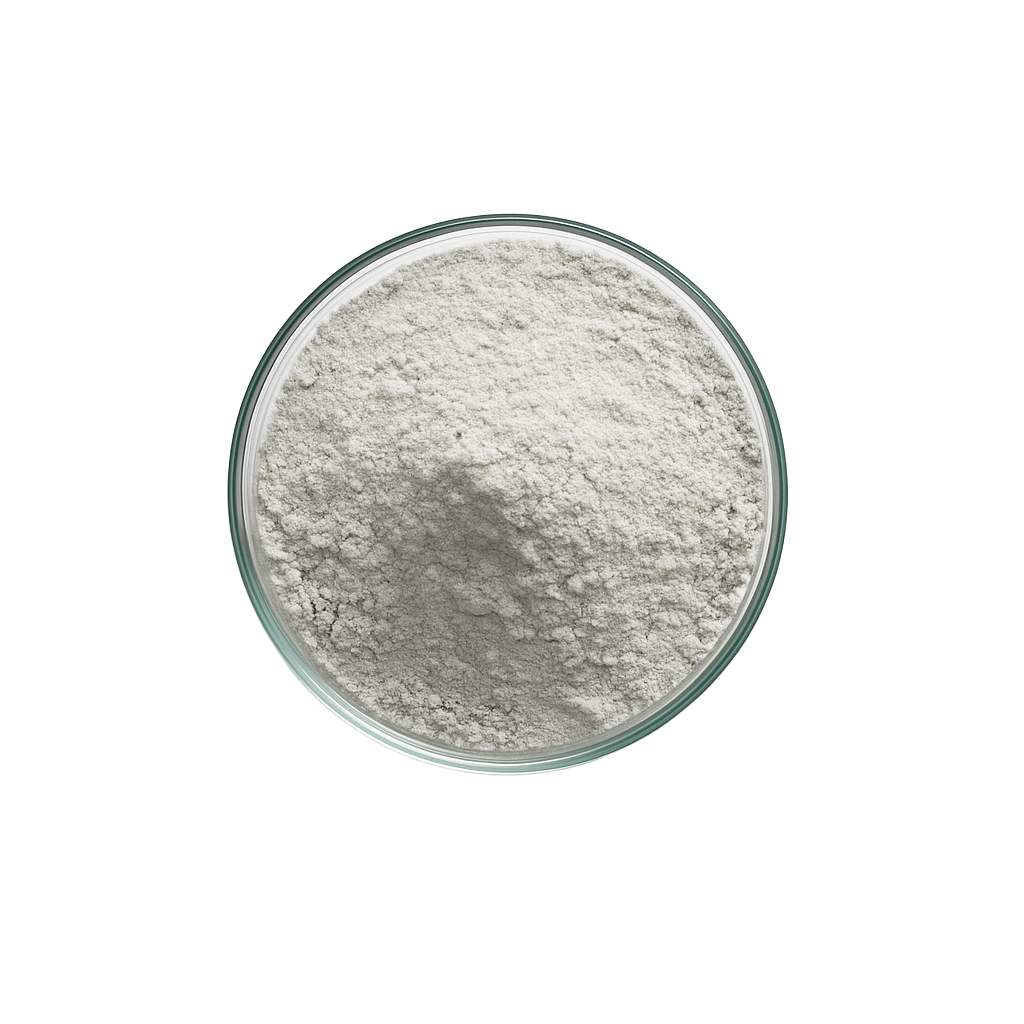

GGBFS

Enhances durability and lowers environmental impact

Ground Granulated Blast Furnace Slag (GGBFS) is a byproduct of the iron and steel industry, transformed into a fine powder to enhance concrete performance.

It improves durability, reduces permeability, and increases resistance to sulfate attacks.

Additionally, GGBFS supports sustainability by lowering carbon footprints, conserving energy, and preserving natural resources like limestone and clay.

RoadCem

Revolutionizing road construction with nanotech for durability

RoadCem is an innovative soil stabilization additive that, when mixed with cement, forms a durable, crack-resistant foundation.

It enhances flexibility, impact resistance, and durability in all weather conditions, reducing excavation needs and material costs.

Ideal for highways, rural roads, industrial floors, and canal linings, RoadCem improves tensile and compressive strength while minimizing environmental impact.

Masheed Commitment to Sustainable Construction

Building Greener Future

At Masheed, sustainability is at the core of our operations. We are committed to providing sustainable cementitious solutions that reduce carbon footprint, conserve natural resources, and promote long-term durability.

By integrating sustainable sourcing, innovative materials, and regulatory compliance, we actively contribute to a more responsible construction industry.